ipcs informed

The specialist for customized conveyor solutions

IPCS: Conveyor technology based on experience

At IPCS, we are specialists in customized conveyor solutions. Our roots are in the automotive industry, where we have gained extensive experience in skid conveyor technology. We are now successfully applying this expertise to other industries. From planning to commissioning, we support you at every stage of your project.

Our services:

- Customized concepts: We develop conveyor solutions that are perfectly customized to your specific requirements.

- Comprehensive planning: From the initial idea to the detailed design - we are your competent partner.

- Flexible solutions: Our systems can be easily adapted to changing production conditions.

- High quality: We rely on high-quality components and precise workmanship.

Conveyor technology - The invisible assistant in production

From the automotive to the non-automotive industry: conveyor technology in action

Imagine you are standing in a huge factory hall. Parts, assemblies and entire products are moving from one workstation to the next. How does this work? The answer lies in the conveyor technology.

Conveyor technology - more than just a conveyor belt

Conveyor technology is far more than just a simple belt that transports products from A to B. It is a highly complex system of machines, sensors and software that ensures that materials and products arrive at the right place in the right order, at the right time.

Conventional conveyor technology in the automotive industry

Conveyor technology is omnipresent in the automotive industry. Large and heavy car bodies are transported just as precisely as small and sensitive electronic components. Chain conveyors, roller conveyors and overhead conveyors are the most commonly used systems.

- Chain conveyors: These conveyors usually transport skids on a transport chain. They are robust and versatile and can be used in hot, dry and painting areas.

- Roller conveyors: Skid or other goods carriers glide on rollers. They are ideal for simple, straightforward transport.

- Overhead conveyors: These systems move the transported goods above the heads of the employees to facilitate the processing of the underside or to enable transport routes on a different level in the production hall. They can contribute to a space-saving and flexible solution right from the planning stage.

Why is conveyor technology so important in the automotive industry?

- Efficiency: The continuous flow of material reduces production time.

- Precision: The exact positioning of the components is crucial for the high quality of the products.

- Flexibility: Conveyor systems can be adapted to different production requirements.

Conveyor technology in the non-automotive industry

However, conveyor technology is not only used in the automotive industry. It also plays a decisive role in other sectors such as mechanical engineering and logistics.

- Mechanical engineering: Large and heavy components are moved with the aid of crane runways and heavy-duty conveyors.

- Logistics: In logistics centres, automatic sorting systems and parcel conveyors ensure a fast and efficient flow of goods.

The future of conveyor technology

Conveyor technology is constantly evolving. New technologies are enabling ever more intelligent and flexible solutions. In future, conveyor systems will be even better integrated into the entire production chain and can therefore contribute to even greater efficiency and productivity.

Would you like to find out more about conveyor technology?

We look forward to answering any questions you may have.

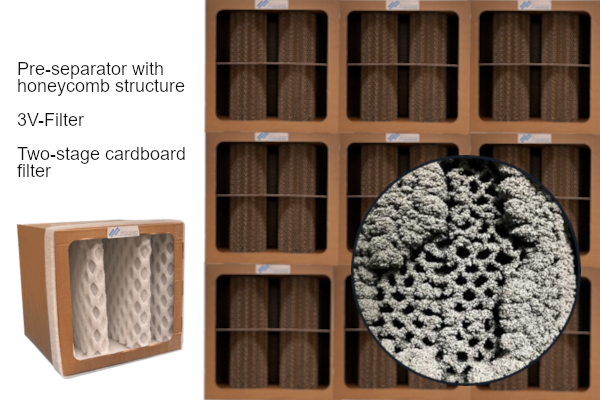

Innovative solutions for clean exhaust air

In addition to our recyclable metal filters, we are now pleased to present our standard cardboard filter systems:

our pre-separator with honeycomb structure, the 3V filter and the two-stage cardboard filter - the perfect solutions for your paint booths!

Pre-separator with honeycomb structure: Our innovative pre-separator with honeycomb structure achieves excellent results in the separation of coarse particles of the overspray. The paint settles in layers in the open honeycombs and on the edges, preventing the coarse particles from coming loose and clogging the fine filter.

3V filter: This filter is a pure fine filter and is equipped with high-quality synthetic fleece. With a filter surface area of approx. 1.5 m², it is able to absorb up to 10 kg of paint.

Two-stage cardboard filter: Our two-stage cardboard filter combines the advantages of the pre-separator with honeycomb structure and the 3V fine filter. The pre-separator separates the coarse particles and prevents the integrated fine filter from clogging too quickly. Thanks to the even distribution of coarse and fine particles within the filter, the filter is able to absorb large quantities of paint.

Why IPCS?

- Innovative technologies

- High efficiency

- Customized solutions for your paint booths

Let's optimize paint separation in your paint booth

together!

Contact us for more information or a personalized consultation.

We look forward to your feedback and questions!

filtermanagement@ipcs.business

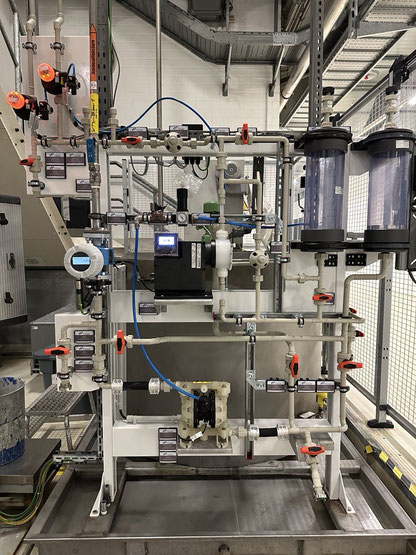

Environmental aspects in the planning of PT systems

IPCS GmbH is your specialist for PT systems. When it comes to cleaning and pre-treatment of workpieces, the focus is on sustainability and efficiency. IPCS supports you from the workpiece analysis and basic design of the system through to the construction, installation and commissioning of the PT system.

IPCS GmbH - Your partner for sustainable PT solutions

- Analysis and optimization of existing systems

- Comprehensive services: Planning, construction, installation

- Customized solutions according to customer requirements

Environmental aspects in planning

- Reduction of wastewater and emissions

- Use of environmentally friendly chemicals

- Energy efficiency by the use of modern technologies

System design

- Basic design of the PT system

- Consideration of the workpiece analysis

- Selection of suitable system components

- Dimensioning of tanks and pumps etc.

Automation and energy efficiency

- Automation and energy efficiency at PT

- Automatic shutdown of pumps during breaks / weekends

Picture 1: Installation of a PT and ED system

Picture 2: Installation of a dosing station

Recyclable filter system from IPCS GmbH

The team at IPCS GmbH has developed a filter system that improves the absorption of overspray in paint booths and is also recyclable.

With our filter systems, we can respond to a wide range of conditions. Depending on the type of paint and the depth of the filter slide-in boxes of your paint booth, we will assemble a suitable combination of pre-separators and fine filters to achieve the best possible paint absorption.

Our pre-separator with honeycomb structure plays a special role here. The honeycomb structure ensures that the paint particles settle better and more easily in the filter. In several tests with different customers, our pre-separator was able to collect significantly more paint in the same amount of time than comparable models.

By optimizing the absorption of the paint by the pre-separator, the fine filter is less loaded, which significantly improves the service life of the fine filter. But that is not the only advantage. As a result of the use of our synthetic filter fleece with filter class M6, significantly less or almost no paint particles pass through the fine filter. Many companies struggle with paint deposits in their exhaust or recirculation systems because their filters pass on too much paint, which settles there. Cleaning these exhaust and recirculation systems and balancing the fans regularly leads to high costs. The excellent filter quality of our filter system minimizes these costs.

Our filter systems are available in various versions made of cardboard or as a sustainable alternative made of pyrolysis-compatible metal.

Would you like to find out more about our filter system?

Then get in touch with our direct contact Uwe Knaus: u.knaus@ipcs.business

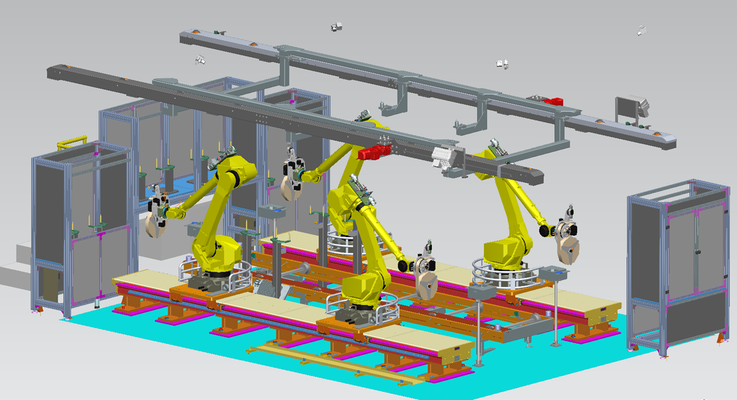

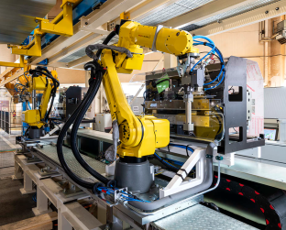

Application, robotics and simulation

In today's world, in which the economic and ecological demands on industrial processes become greater, it is all the more important to continuously make production facilities more efficient and sustainable.

Our team of technicians and engineers will support you in this challenge. We develop and realize automation solutions for you in all areas of the general and automotive industry. Our portfolio includes processes of the following areas:

- PVC

- Wet paint

- Handling operations

- Automatic hole covering

We elaborate the optimum solution for your individual application. As a manufacturer-independent integrator, we will find the right combination of robots, application technology and software for you. We implement existing specifications and customer requirements, but also consult you during the concept development phase with our expertise based on a large number of reference projects.

We also offer the offline simulation of robot stations as a service. With the Process Simulate tool, we can support you in the design, analysis, simulation and optimization of production systems. Our cycle time and reachability analyses ensure maximum reliability in the planning and implementation of the real system.

Before the robot cells are dispatched, they are pre-assembled and commissioned in our pre-assembly hall. This gives us the opportunity to test the application technology and the process used to reduce commissioning times at the customer's premises.

Furthermore, our PVC test stand offers the possibility of determining process parameters and validating new PVC material and nozzles.

We look forward to consulting you in a personal meeting.

Our employee Uwe Knaus is primarily responsible for the development of the recyclable filters.

We made it - 2nd place in the Innovation Award 2023!

The jury of the ife Board of Trustees has honoured our new product, a recyclable filter, with second place in the LOSGRÖSSE 1+ innovation award.

Many paint shops have cardboard filters that are replaced with a new cardboard filter once they have reached their filling level. The filled cardboard filter is then incinerated by a specialised waste disposal company or disposed of at a landfill site. In Germany, more than 2 million soiled cardboard filters from paint booths and spray booths are disposed of every year, resulting in around 22.5 million kilograms of CO₂.

We set ourselves the task of developing a more sustainable alternative for the cardboard filters that produces less waste and ensures a better CO₂ balance.

We have now achieved this with our newly developed recyclable filter! The filter is made of pyrolysis-compatible material and has the standard market dimensions, meaning that cardboard filters can be easily replaced with our recyclable filter.

This achievement has now been recognised by the ife Institute for Customised Manufacturers with second place in the Innovation Award. The Innovation Award is organised under the patronage of the President of the European Economic Senate. All applications are judged in the categories of creativity, market success, sustainability, savings potential and significance by a jury consisting of members of the current ife Board of Trustees, which is made up of managers from practice, consultancy and science.

Thank you very much for the excellent assessment! We are delighted with this ranking and feel honoured.

Would you like to find out more about our recyclable filter? Get in touch with us:

Contact person: Uwe Knaus u.knaus@ipcs.business

IPCS speech at the EUROSURFAS-The International Surface Treatment Event in Barcelona: 16.09.2021

Our Head of Sales Spain Daniel Alonso will give a speech on September 16, 2021 at 11 a.m.

"New System for Overspray Dry Separation: Efficient, Recyclable and Sustainable"

at the EUROSURFAS-The International Surface Treatment Event in Barcelona / Exhibition Center.

You are cordially invited!

new branch office in Spain: 01.09.2021

On the 1st of September IPCS GmbH opens a new subsidiary in Barcelona, Spain:

Innovative Paint & Conveyor Systems S.L.U.

The creation of this new office will allow us to offer the Spanish market innovative solutions for surface treatment facilities and new unique products.

IPCS / Spain

Announcement change of name

Dear Ladies and Gentlemen,

with this letter we want to inform you that our company will be renamed.

The company as you know as IBCS GmbH, will be called from 2nd July, as IPCS GmbH.

With the new name, we also want to reflect the entire range of services offered by our company.

Innovative paint shops and conveyor systems, tailormade to the needs of our customers.

Your personal contacts are there for you as usual. The company data such as address, bank details,

commercial register number etc. remain unchanged.

The existing e-mail addresses remain active. At the same time, the new e-mail addresses with

uniform notation will also apply from now on: a.mustermann@ipcs.business

(First letter of the First name.Surname@ipcs.business)

We ask you to change our new company name in your master data accordingly.

For any kind of questions feel free to contact us.

We look forward to a continuation of our good and trusting cooperation.